Job Operations Setup Data Tags

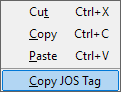

You can easily find which Job Operation Planner input field is associated with which JOS Data Tag, by holding your mouse over the field; the displayed tooltip includes the related data tag. Additionally, if you right-click on the field, the pop-up menu includes a Copy JOS Tag option. This option copies the data tag name into the Windows clipboard, so that you can paste it into your code generator, macro, for format file.

The following is an alphabetical listing of JOS Data Tags, use the filter selectors to display targeted information.

| Data Tag | Description | Area Type | Context | Data Element | Notes | Application |

|---|---|---|---|---|---|---|

| abrasive | A list of different abrasive types, as defined by the user. | Step Integer |

Op | abrasive | 0 = None 1 = Garnet 2 = Cu Slag 3 = Olivine 4 = Other |

AF |

| app_type | Job Application Type | Job Integer |

Header | app_type | 1 = Milling 2 = Turning 3 = Fabrication 4 = Wire EDM 5 = Burner 6 = Router 7 = Contour |

All |

| bell_dia | Bell diameter of a center drill. | Step Float |

Tool | bell_dia | PM, AM, FFM, AT | |

| body_dia | Body diameter of a center drill. | Step Float |

Tool | body_dia | PM, AM, FFM, AT | |

| boff | Secondary length offset register number used for the back edge of a groove tool. Applicable for Groove element

(not Groove Rough) and Profile Processes when using a groove tool. The value of LOFF is changed

to that specified by BOFF when the tool moves in the back-edge direction. |

Step Integer |

Step | boff | PT, AT | |

| ccw | Number specifying whether the tool is clockwise or counter-clockwise. | Step Integer |

Tool | ccw | 0 = Clockwise 1 = Counter-Clockwise |

PM, AM, FFM, PT, AT |

| centrcut | Number specifying whether the end, ball, or bull mill is center-cutting. | Step Integer |

Tool | centrcut | 0 = Not center-cutting 1 = center-cutting |

PM, AM, FFM, AT |

| ch_type | Chamfer type of a tap tool. | Step Integer |

Tool | ch_type | 0 = Bottoming 1 = Plug 2 = Taper |

PM, AM, FFM, PT, AT |

| clamp_ctg | The Custom Tool Graphic (CTG) file used to display clamps. | Job String |

Work_setup | clamp_ctg | AF | |

| clamp1_pos | The position of the first work piece clamp. | Job Float |

Work_setup | clamp1_pos | AF | |

| clamp2_pos | The position of the second work piece clamp. | Job Float |

Work_setup | clamp2_pos | AF | |

| clamp3_pos | The position of the third work piece clamp. | Job Float |

Work_setup | clamp3_pos | AF | |

| clamp4_pos | The position of the fourth work piece clamp. | Job Float |

Work_setup | clamp4_pos | AF | |

| clr_type | What type of clearance is around a punch die. | Step Integer |

Tool_assembly | clr_type | 0 = Standard 1 = Positive 2 = Negative 3 = None |

AF |

| convcutff | Conventional cut feed factor. Used by adaptive roughing processes to reduce primary feed for conventional cutting moves. | Step Float |

Op | convcutff | 0.75 | AM, FFM, AT |

| coolant | A number specifying the coolant used in the operation. | Step Integer |

Op | coolant | 0 = None 1 = Flood 2 = Mist 3 = Through 4 = Air |

PM, AM, FFM, PT, AT |

| coolant | Whether the water assist is turned on. | Step Integer |

Op | coolant | 0 = No 1 = Yes |

AF |

| corner_abrasive | The abrasive flow during corner or slowdown cutting. | Step Float |

Op | corner_abrasive | AF | |

| corner_comp | A special compensation factor, different than kerf width. Slower feed rates tend to create larger kerf widths and these fields are for this compensation. | Step Float |

Op | cut_comp | AF | |

| corner_duty | The duty cycle of a laser during corner cutting. | Step Float |

Op | corner_duty | AF | |

| corner_feed | The feed in units per minute during laser corner cutting or arc/corner cutting. | Step Float |

Op | cut_feed | AF | |

| corner_flow | Flow rate for waterjet process. | Step Float |

Op | AF | ||

| corner_freq | The frequency of laser pulsing during corner cutting. | Step Integer |

Op | corner_freq | AF | |

| corner_gas | The gas used for laser corner cutting. | Step Integer |

Op | corner_gas | 0 = O2 1 = CO2 2 = NI 3 = AR 4 = Air 5 = Other |

AF |

| corner_power | The laser power during laser corner cutting. | Step Integer |

Op | corner_power | AF | |

| corner_press | The gas pressure during laser corner cutting or the water pressure during corner or slowdown cutting. | Step Float |

Op | corner_press | AF | |

| corner_pulse | How the laser is pulsed during corner cutting. | Step Integer |

Op | corner_pulse | 0 = Continuous 1 = Gated 2 = Super 3 = Hyper 4 = Other |

AF |

| corner_stand | The distance between the material and the nozzle during corner or slowdown cutting for waterjet. | Step Float |

Op | corner_stand | AF | |

| corner_type | How to negotiate a sharp corner or arc. | Step Integer |

Op | corner_type | 0 = None 1 = Slowdown 2 = Round 3 = Loop 4 = Other |

AF |

| cradius | The corner radius of the tool. | Step Float |

Tool | cradius | JOS(tl_dia)/2 for Ball Mill | PM, AM, FFM, PT, AT, AF |

| created | The date the job was created. | Job String |

Job_info | created | All | |

| createdfor | Who or what the job is created for. | Job String |

Job_info | createdfor | All | |

| creator | Who created the Job. | Job String |

Job_info | creator | All | |

| cut_comp | A special compensation factor different than kerf width. Slower feed rates tend to create larger kerf widths and these fields are for this compensation. | Step Float |

Op | cut_comp | AF | |

| cut_duty | The duty cycle of a laser during normal cutting. | Step Integer |

Op | cut_duty | All | |

| cut_factor | Can be used for a variety of things, including a material thickness factor for determining the location of the "waist" or the narrowest. | Step Float |

Op | cut_factor | AF | |

| cut_feed | The feed in units-per-minute during normal laser cutting, burning, cutting, scribing, and secondary operations. | Step Float |

Op | cut_feed | AF, AW | |

| cut_fixt | The Fixture layer numbers, as configured in Job Info - Work Setup. | Job String |

Work_setup | cut_fixt | PM, AM, FFM, PT, AT | |

| cut_flow | Abrasive flow rate during normal cutting. Usually expressed in lbs/min or g/min. | Step Integer |

Op | cut_flow | AF | |

| cut_freq | The frequency of laser pulsing during normal cutting. | Step Integer |

Op | cut_freq | AF | |

| cut_gas | The gas used for laser normal cutting. | Step Integer |

Op | cut_gas | 0 = O2 1 = CO2 2 = NI 3 = AR 4 = Air 5 = Other |

AF |

| cut_matl | The Stock layer numbers, as configured in Job Info - Work Setup. | Job String |

Work_setup | cut_matl | PM, AM, FFM, PT, AT | |

| cut_power | The laser power during normal laser cutting. | Step Integer |

Op | cut_power | AF | |

| cut_press | The gas pressure during normal laser cutting or the water pressure during normal waterjet cutting (normally measured in psi or MPa). | Step Float |

Op | cut_press | AF | |

| cut_pulse | How long the laser is pulsed during normal cutting. | Step Integer |

Op | cut_pulse | 0 = Continuous 1 = Gated 2 = Super 3 = Hyper 4 = Other |

AF |

| cut_stand | The distance between the material and nozzle during normal cutting for waterjet. | Step Float |

Op | cut_stand | AF | |

| cut_void | The Void layer numbers, as configured in Job Info - Work Setup. | Job String |

Work_setup | cut_void | PM, AM, FFM, PT, AT | |

| cutdepth | The depth of cut for rough and face milling. | Step Float |

Op | cutdepth | PM, AM, FFM, AT | |

| cutfin | The finish allowance for copy and surface milling. | Step Float |

Op | cutfin | PM, AM, FFM, AT, AW | |

| cutwidth | The width of cut for rough and face milling. | Step Float |

Op | cutwidth | PM, AM, FFM, AT | |

| cycle | A number specifying the canned drill cycle. | Step Integer |

Op | cycle | 0 = Cycle 1 1 = Cycle2 2 = Cycle3 3 = Cycle4 |

PM, AM, FFM, PT, AT |

| dead_zone_x | The X dimensions around the clamps where the tool cannot move. | Step Float |

Work_cell | dead_zone_x | AF | |

| dead_zone_y | The Y dimensions around the clamps where the tool cannot move. | Step Float |

Work_cell | dead_zone_y | AF | |

| diameter | Used for speed and feed calculations. | Job Float |

tl_dia | JOS(tl_dia), if available. | PM, AM, FFM, AT | |

| die_cl | The clearance needed by a punch die. | Step Float |

Tool_assembly | die_cl | AF | |

| doff | A number specifying the distance offset register number. | Step Integer |

Step | doff | AF | |

| dwellsec | Number of dwell seconds on Hole Operations and after completing piercing operations. In waterjet cutting, the dwell time can let the machine's pressures and/or abrasives stabilize, or come up to pressure. | Step Float |

Op | dwellsec | PM, AM, FFM, PT, AT, AF | |

| event_time | Time associated with an Event Op. This time is added to your total cycle time. | Step Integer |

event_time | All | ||

| fdmode | A number specifying which unit feeds are output in. | Step Integer |

Step | fdmode | 1 = UPR 2 = UPM 3 = UPH (nibbling in Fabrication) |

PM, AM, FFM, PT, AT, AF |

| feedupm1 | The primary feed rate in units (inches or millimeters) per minute. | Step Float |

Op | feedupr | PM, AM, FFM, PT, AT | |

| feedupm2 | The secondary feed rate in units (inches or millimeters) per minute. | Step Float |

Op | feedupr2 | PM, AM, FFM, PT, AT | |

| feedupm3 | The secondary feed rate in units (inches or millimeters) per minute. | Step Float |

Op | feedupr3 | PM, AM, FFM, PT, AT | |

| feedupr | Provided for translation of older .jof formulas. |

Step Float |

Op | feedupr1 | JOS(feedupr1) | PM, AM, FFM, PT, AT |

| feedupr1 | The primary feed rate in units (inches or millimeters) per revolution. | Step Float |

Op | feedupr | PM, AM, FFM, PT, AT | |

| feedupr2 | A secondary feed rate in units (inch or millimeters) per revolution. | Step Float |

Op | feedupr2 | PM, AM, FFM, PT, AT | |

| feedupr3 | The secondary feed rate in units (inches or millimeters) per revolution. | Step Float |

Op | feedupr3 | PM, AM, FFM, PT, AT | |

| feedupt1 | The primary feed rate in units (inches or millimeters) per tooth. | Step Float |

Op | feedupt | PM, AM, FFM, PT, AT | |

| feedupt2 | The secondary feed rate in units (inches or millimeters) per tooth. | Step Float |

Op | feedupt2 | PM, AM, FFM, PT, AT | |

| feedupt3 | A secondary feed rate in units (inch or millimeters) per tooth. | Step Float |

Op | feedupt3 | PM, AM, FFM, PT, AT | |

| flrallow | The floor allowance for rough and face milling operations. | Step Float |

Op | flrallow | PM, AM, FFM, AT | |

| flush_press | What the pressure on the flush is during EDM operations. | Step Integer |

Op | flush_press | 0 = Low 1 = Medium 2 = High 3 = Other |

AW |

| flush_type | How the flush is applied during EDM operations. | Step Integer |

Op | flush_type | 0 = Coaxial 1 = Submerged 2 = Other |

AW |

| geometry | A number specifying the geometry for the tool. | Step Integer |

Tool | geometry | Varies by tool type: 0 = Standard 1 = Parabolic 2 = High Spiral Tap: Twist Drill: |

PM, AM, FFM, PT, AT |

| graphics | The custom tool graphics (CTG) file associated with the current tool. | Step String |

Tool | graphics | All | |

| hd_section | The Section number of the header data block in the current job. | Job String |

Header | section | All | |

| hd_type | The Type (last four digits of Section number) number of the header block in the job. | Job Integer |

JOS(hd_section) modulo 10000 | All | ||

| hold_down_ctg | The Custom Tool Graphic (CTG) file used to display the hold down. | Job String |

Work_setup | hold_down_ctg | AF | |

| home1_x | The Home Position X coordinate. | Job Float |

Work_setup | home1_x | PM, AM, FFM, PT, AT | |

| home1_y | The Home Position Y coordinate. | Job Float |

Work_setup | home1_y | PM, AM, FFM, AT | |

| home1_z | The Home Position Z coordinate. | Job Float |

Work_setup | home1_z | PM, AM, FFM, PT, AT | |

| home2_x | Turret 2 Home Position X coordinate. | Job Float |

Work_setup | home2_x | AT | |

| home2_y | Turret 2 Home Position Y coordinate. | Job Float |

Work_setup | home2_y | AT | |

| home2_z | Turret 2 Home Position Z coordinate. | Job Float |

Work_setup | home2_z | AT | |

| home_plnchg | Plane Change positioning method. | Job Integer |

Work_setup | home_plnchg | PM, AM, FFM | |

| home_tlchg | Tool Change positioning method. | Job Integer |

Work_setup | home_tlchg | PM, AM, FFM | |

| home_use | Specify Home Position option. | Job Integer |

Work_setup | home_use | PM, AM, FFM, PT, AT | |

| incl_ang | The included angle at the top of a turning tool. | Step Integer |

Tool | incl_ang | PT, AT | |

| indexable | Tells whether the tool is auto-indexable. | Step Integer |

Tool_assignment | indexable | 0 = Not Indexable 1 = Indexable |

AF |

| insrt_id | The standard insert identifier. | Step Stringinsrt_id |

Tool | insrt_id | PT, AT | |

| insrtsiz | The size of a turning insert. | Step Float |

Tool | insrtsiz | PT, AT | |

| intol | The surface tolerance for copy milling operations. | Step Float |

Op | intol | PM, AM, FFM, AT | |

| jb_section | The Section number of the job_info data block in the current job. | Job String |

Job_info | section | All | |

| jb_type | The Type (last four digits of Section number) number of the job_info block in the current job. | Job Integer |

JOS(jb_section) modulo 10000 | All | ||

| job_note | The notes about the job. As part of the upward compatibility, this will be checked for variable assignments. | Job String |

Job_info | notes | All | |

| jof_file | The path and filename of the file which was read into the current process model. When the file is written out it will take the name of the current job file. | Job String |

Header | file | All | |

| jsf_tool | The jsf tool number that approximates what this step does (obsolete). | Step Integer |

Derived from the Tool Assembly, Section number, and other information. | All | ||

| kerf_width | The total width that is cut from the material using waterjet cutting, laser cutting, burning, cutting. | Step Float |

Op | kerf_width | AF, AW | |

| ldedgact | The actual lead edge angle of a turning tool in degrees taking into account its orientation. | Step Float |

Derived from the lead angle and the X/Z Ref setting. |

PT, AT | ||

| ldedgclr | The clearance from the leading edge of a turning tool in degrees. | Step Float |

Op | ldedgclr | PT, AT | |

| ldedgeff | The effective leading edge angle of a turning tool in degrees, including clearance. | Step Float |

Derived from the lead angle, lead edge clearance,

and the X/Z Ref orientation. |

PT, AT | ||

| leadang | The lead angle of a turning tool in degrees, the 0 reference is selected by the leadref tag. |

Step Float |

Tool_assignment | leadang | PT, AT | |

| leadref | Number encoding the zero reference for the lead angle. | Step Integer |

Tool_assignment | leadref | 0 = X reference angle 1 = Z reference |

PT, AT |

| len_pset | The preset length of the tool. | Step Float |

Tool_assembly | len_pset | PM, AM, FFM | |

| length | The length of a tool for rectangle, obround, diamond, and special punches. | Step Float |

Tool | length | AF | |

| loff | The length offset register number. | Step Integer |

Step | loff | PM, AM, FFM, PT, AT, AF | |

| lubricant | The lubricant used on the work piece. | Job Integer |

Work_setup | lubricant | 0 = Both 1 = Bottom 2 = Top 3 = None 4 = Through |

AF |

| mach_desc | A string describing the type of machine the job was written for. | Job String |

Mapped from header, app_type | All | ||

| mach_limitx | The extent of the machine's travel in X. | Job Float |

Work_cell | mach_limitx | AF | |

| mach_limity | The extent of the machine's travel in Y. | Job Float |

Work_cell | mach_limity | AF | |

| mach_path | The path where any .smf or .cgt files associated with this job will be found. |

Job String |

Work_cell | mach_path | All | |

| matl_desc | A description of the material used in the job. | Job String |

Material | descrip | All | |

| matl_file | The part material file used by the speed and feed calculator. | Job String |

Material | matl_file | All | |

| matl_name | The name of the part material. | Job String |

Material | matl_name | All | |

| matl_notes | Notes written about the material. | Job String |

Material | notes | All | |

| matl_thick | The thickness of the stock material. | Job Float |

Material | matl_thick | AF, AW | |

| max_depth | The maximum depth a grooving tool can work to. | Step Float |

Tool | max_depth | PT, AT | |

| minbr_dia | The minimum boring diameter for bore tools. | Step Float |

Tool | minbr_dia | PM, AM, FFM, AT | |

| mt_section | The Section number of the material data block in the current job. | Job String |

Material | section | All | |

| mt_type | The Type (last four digits of Section number) number of the material data block in the current job. | Job Integer |

JOS(mt_section) modulo 10000 | All | ||

| n_flutes | The number of flutes on a hole or milling tool. | Step Integer |

Tool | n_flutes | PM, AM, FFM, PT, AT | |

| nc_date | The date the job was last coded. | Job String |

Job_info | nc_date | All | |

| nc_file | The name of the NC code file last written from this job. | Job String |

Job_info | nc_file | All | |

| nc_runtime | The time that it would take to run the code as the job was last coded. | Job String |

Job_info | nc_runtime | All | |

| nc_size | The size of the code file last written from this JOS. | Job Integer |

Header | nc_size | All | |

| nc_time | The time that the job was last coded. | Job String |

Job_info | nc_time | All | |

| neckdia | The relieved neck diameter of a thread mill tool. | Step Float |

Tool | neckdia | PM, AM, FFM, AT | |

| op_desc | The current operation description. | Step String |

Op | descrip | All | |

| op_pitch | The primary feed rate in units per revolution for tapping. | Step Float |

Op | feedupr | PM, AM, FFM, PT, AT | |

| op_section | The Section number of the operation in the current step. | Step String |

Op | section | PM, AM, FFM, PT, AT, AF | |

| op_tpu | The primary feed rate in threads per unit for tapping. | Step Float |

Op | feedupr | PM, AM, FFM, PT, AT | |

| op_type | The Type (last four digits of Section number) number of the operation in the current step. | Step Integer |

JOS(op_section) modulo 10000 | All | ||

| op_usrnam | The operation unique identifier. | Step String |

Op | user_name | All | |

| ornttn | Number encoding the orientation of the tooling (used to be cut direction). | Step Integer |

Tool_assignment | ornttn | 0 = Down Left 1 = Up Left 2 = Down Right 3 = Up Right 4 = Down 5 = Up 6 = Left 7 = Right |

PT, AT |

| outfeed1 | Primary feed rate in the units specified by the feed mode. | Step Float |

If feed mode is upr: JOS(feedupr1) If feed mode is upm: JOS(feedupm1) |

PM, AM, FFM, PT, AT | ||

| outfeed2 | A secondary feed rate in the units specified by the feed mode. | Step Float |

If feed mode is upr: JOS(feedupr2) If feed mode is upm: JOS(feedupm2) |

PM, AM, FFM, PT, AT | ||

| outfeed3 | A secondary feed rate in the units specified by the feed mode. | Step Float |

If feed mode is upr: JOS(feedupr3) If feed mode is upm: JOS(feedupm3) |

PM, AM, FFM, PT, AT | ||

| outol | The surface out tolerance for copy milling operations. | Step Float |

Op | outol | PM, AM, FFM, AT | |

| outspeed | The speed, in the units specified by the speed mode. | Step Float |

If speed mode is upm: JOS(speedcss) |

PM, AM, FFM, PT, AT | ||

| over_trvl_ctg | The Custom Tool Graphic (CTG) file used to display the over-travel area. | Job String |

Work_setup | over_trvl_ctg | AF | |

| passdpth | The depth of the pass for rough turning. | Step Float |

Op | passdpth | PT, AT | |

| passwdth | The width of pass for Grooving and Face Grooving. | Job Float |

Op | passwdth | PT, AT | |

| pekdpth1 | The initial peck depth for peck drilling. | Step Float |

Op | pekdpth1 | PM, AM, FFM, PT, AT | |

| pekdpth2 | The peck increment for peck drilling. | Step Float |

Op | pekdpth2 | PM, AM, FFM, PT, AT | |

| pi | The value of PI to fifteen places. | Job Float |

All | |||

| pierce_duty | The duty cycle of a laser during piercing. | Step Integer |

Op | pierce_duty | AF | |

| pierce_factor | This field can be used for a variety of things; including a material thickness factor for determining the location of the "waist." | Step Float |

Op | pierce_factor | AF | |

| pierce_flow | The abrasive flow rate during low pressure cycle of the piercing process. Usually expressed in lbs/min or g/min. | Step Float |

Op | pierce_flow | AF | |

| pierce_focus | Focus distance for the laser during piercing for laser cutting. | Step Float |

Op | pierce_focus | AF | |

| pierce_freq | The frequency of laser pulsing during piercing. | Step Integer |

Op | pierce_freq | AF | |

| pierce_gas | The gas used for laser piercing. | Step Integer |

Op | pierce_gas | 0 = O2 1 = CO2 2 = NI 3 = AR 4 = Air 5 = Other |

AF |

| pierce_power | The laser power during piercing for laser cutting. | Step Float |

Op | pierce_power | AF | |

| pierce_press | Gas pressure for piercing during laser cutting or the lower value of waterjet system pressure when dual pressure compensation is used during piercing. | Step Float |

Op | pierce_press | AF | |

| pierce_pulse | How the laser is pulsed during piercing. | Step Integer |

Op | pierce_pulse | 0 = Continuous 1 = Gated 2 = Super 3 = Hyper 4 = Other |

AF |

| pierce_stand | The distance between the material and the nozzle during piercing for waterjet. | Step Float |

Op | pierce_stand | AF | |

| pierce_time | Time, in seconds, to pierce the material. | Step Float |

Op | pierce_time | AF | |

| pierce_type | The type of piercing method:

|

Step Integer |

Op | pierce_type | 0 = None 1 = Stationary 2 = Moving 3 = Plunge 4 = Other |

AF |

| pitch | The tap pitch for tap tooling. | Step Float |

Tool | pitch | PM, AM, FFM, PT, AT | |

| plt_dia | The pilot diameter for counterbores. | Step Float |

Tool | plt_dia | PM, AM, FFM, AT | |

| plt_len | The pilot length for counterbores. | Step Float |

Tool | plt_len | PM, AM, FFM, AT | |

| power_reg | The power register to use during EDM operations. | Step Integer |

Op | power_reg | AW | |

| prog_id | A program identifier of the output code file. | Job String |

Job_info | prog_id | All | |

| prt_desc | A description of the part the job makes. | Job String |

Job_info | prt_desc | All | |

| q_level | Information for the operator only. It lets the operator know what the quality of the cut should be. | Step Float |

Op | q_level | AF | |

| refdia | A reference diameter for calculating speeds and feeds for turning operations. | Step Float |

Step | refdia | PT, AT | |

| rev | The number of revisions of this job. | Job Integer |

Header | rev | All | |

| rev_date | The date the job (.pm4 and .jof files) were last modified. | Job String |

Job_info | rev_date | All | |

| rpm | The speed in revolutions per minute. | Step Float |

Op | speedcss | PM, AM, FFM, PT, AT | |

| shape | Tells which shape of turning insert. | Step Integer |

Tool | shape | 1 = Diamond 2 = Hexagon 3 = Octagon 4 = Parallelogram 5 = Pentagon 6 = Rectangle 7 = Round 8 = Square 9 = Triangle |

PT, AT |

| shape_ang | A composite of the shape and included angle. | Step Integer |

JOS(shape)*1000 + JOS(incl_ang) | PT, AT | ||

| sheet_x | X dimension of the blank. | Job Float |

Material | sheet_x | AF | |

| sheet_y | Y dimension of the blank. | Job Float |

Material | sheet_y | AF | |

| sideang | The side angle for end, ball, bull, and face mills. | Step Float |

Tool | sideang | PM, AM, FFM, PT, AT | |

| slope | The slope angle in degrees of the sides of a trapezoid. | Step Float |

Tool | slope | AF | |

| smf1_master | The file name of the .smf file used when coding. |

Job String |

Work_cell | smf1_master | All | |

| smf1_mfull | The complete expanded filename of the .smf file used when coding. |

Job String |

Derived from mach_path and smf1_master. |

All | ||

| smf1_sfull | The complete path and filename of the slave .smf file used for turret 1 (milling operations). |

Job String |

Derived from mach_path and smf1_slave. |

AT | ||

| smf1_slave | The filename for the slave .smf file for turret 1 (milling operations). |

Job String |

Work_cell | smf1_slave | AT | |

| smf2_master | The file name of the .smf file for turret 2 (turning operations). |

Job String |

Work_cell | smf2_master | AT | |

| smf2_mfull | The complete expanded filename of the master .smf file for turret 2 (turning operations). |

Job String |

Derived from mach_path and smf2_master. |

All | ||

| smf2_sfull | The complete path and filename of the slave .smf file used for turret 2 (turning operations). |

Job String |

Derived from mach_path and smf2_slave. |

AT | ||

| smf2_slave | The filename for the slave .smf file for turret 2 (turning operations). |

Job String |

Work_cell | smf2_slave | AT | |

| speed_adjust | Used to override any calculated data from the Arc/Corner Cut section. | Step Integer |

Op | speed_adjust | AF | |

| speedcss | The constant surface speed in units (feet or meters) per minute. | Step Float |

Op | speedcss | PM, AM, FFM, PT, AT | |

| speedfact | A factor that translates speed linear units into general linear units (feet to inches or meters to millimeters). | Step Float |

PM, AM, FFM, PT, AT | |||

| spindle | The spindle direction as number suitable for multiplication. | Step Integer |

If spindle is clockwise = 1 Otherwise = (-1). |

PM, AM, FFM, PT, AT | ||

| spmode | Specifies the units of the output speed. | Step Integer |

Step | spmode | 1 = SUPM (ft/min or m/min) 2 = RPM |

PM, AM, FFM, PT, AT |

| standoff | The standoff distance fro laser cutting, burning, and waterjet cutting. | Step Float |

Op | standoff | AF | |

| st_desc | The current step description. | Step String |

Step | descrip | All | |

| st_notes | The current step notes. | Step String |

Step | notes | All | |

| st_section | The Section number of the current step. | Step String |

Step | section | PM, AM, FFM, PT, AT, AF | |

| st_type | The Type (last four digits of Section number) number of the current step. | Step Integer |

JOS(st_section) modulo 10000 | All | ||

| start_angle | The initial angle a punch tool is set in the machine. | Step Float |

Tool_assignment | start_angle | AF | |

| station | An obsolete term for the tool number. | Step Float |

Tool_assignment | tl_num | All | |

| station_size | The size of the tool station. | Step Float |

Tool_assignment | station_size | AF | |

| step_num | The current step number. | Step Integer |

Step | user_name | All | |

| stepover | The stepover for copy milling operations. | Step Float |

Op | stepover | PM, AM, FFM, AT | |

| stroke_feed | The stroke feed for punching operations. | Step Float |

Op | stroke_feed | AF | |

| ta_section | The Section number of the tool assignment, in the current step. | Step String |

Tool_assignment | section | All | |

| ta_type | The Type (last four digits of Section number) number of the tool assignment, in the current step. | Step Integer |

JOS(ta_section) modulo 10000 | All | ||

| ta_usrnam | The current tool's unique identifier. | Step String |

Tool_assignment | user_name | All | |

| threadang | The included thread angle of a thread mill tool. | Step Float |

Tool | threadang | PM, AM, FFM, AT | |

| tipangl | The tip angle in degrees of a drill. | Step Float |

Tool | tipangl | PM, AM, FFM, PT, AT | |

| tipdia | The tip diameter of a chamfer and rounding mill. | Step Float |

Tool | tipdia | PM, AM, FFM, AT | |

| tl_desc | The current tool description. | Step String |

Tool | descrip | All | |

| tl_dia | The diameter of a tool in inches or millimeters. | Step Float |

Tool | tl_dia | PM, AM, FFM, PT, AT, AF | |

| tl_len | The cutting length of a tool in inches or millimeters. | Step Float |

Tool | tl_len | PM, AM, FFM, PT, AT, AW | |

| tl_mat | The tool material (the values may be altered using the user list file). | Step Integer |

Tool | tl_mat | Mill/Turn Defaults: 0 = HSS 1 = Carbide 2 = Cobalt 3 = Ceramic Wire EDM: 0 = Brass 1 = Zinc Coated 2 = Molybdenum 3 = Copper 4 = Special |

PM, AM, FFM, PT, AT, AW |

| tl_num | The current tool number. | Step Integer |

Tool_assignment | tl_num | PM, AM, FFM, PT, AT | |

| tl_section | The Section Number of the tool in the current step. | Step String |

Tool | section | All | |

| tl_type | The Type (last four digits of Section number) number of the cutting tool in the current step. | Step Integer |

JOS(tl_section) modulo 10000 | All | ||

| tl_usrdesc | Adds text to the Description field, allowing | Step String |

Tool | user_desc | All | |

| tl_usrnam | The current tool unique identifier. | Step String |

Tool | user_name | All | |

| tm_notes | The current tool notes. | Step String |

Tool_assembly | notes | All | |

| tm_section | The Section number of the assembly in the current step. | Step String |

Tool_assembly | section | All | |

| tm_type | The Type (last four digits of Section number) number of the tool assembly in the current step. | Step Integer |

JOS(tm_section) modulo 10000 | All | ||

| tmp1_master | The filename of the .cgt file used when coding. |

Job String |

Work_cell | tmp1_master | All | |

| tmp1_mfull | The complete expanded filename of the .cgt file used when coding. |

Job String |

Derived from mach_path and tmp1_master. |

All | ||

| tmp1_sfull | The complete path and filename to the slave .cgt file for turret 1 (milling operations). |

Job String |

AT | |||

| tmp1_slave | The filename for the slave .cgt file for turret 1 (milling operations). |

Job String |

Work_cell | tmp1_slave | AT | |

| tmp2_master | The filename of the master .cgt for turret 2 (turning operations). |

Job String |

Work_cell | tmp2_master | AT | |

| tmp2_mfull | The complete expanded filename to the master .cgt file for turret 2 (turning operations). |

Job String |

Derived from mach_path and tmp2_master. |

AT | ||

| tmp2_sfull | The complete path and filename to the slave .cgt file for turret 2 (milling operations). |

Job String |

Derived from mach_path and tmp2_slave. |

AT | ||

| tmp2_slave | The filename for the slave .cgt file for turret 2 (milling operations). |

Job String |

Work_cell | tmp2_slave | AT | |

| tpu | The tap pitch measured in threads per inch or millimeter. | Step Float |

Tool | pitch | PM, AM, FFM, PT, AT | |

| trap_door_ctg | The Custom Tool Graphic (CTG) file used to display the work bench trap door. | Job String |

Work_setup | trap_door_ctg | AF | |

| tredgact | The actual trailing edge angle of a turning tool in degrees taking into account its orientation. | Step Float |

Derived from the lead angle the insert shape and

the X/Z Ref setting. |

PT, AT | ||

| tredgclr | The clearance from the trailing edge of a turning tool in degrees. | Step Float |

Op | tredgclr | PT, AT | |

| tredgeff | The effective trailing edge angle of a turning tool in degrees including clearance. | Step Float |

Derived from the lead angle, tool shape, trailing clearance, and orientation. |

PT, AT | ||

| turret | The turret number for the tool. | Step Integer |

Tool_assignment | turret | PT, AT | |

| turtool | Concatenation of the turret number and tool number. | Step String |

JOS(tl_num):JOS(turret) | PT, AT | ||

| unfdmode | A composite of the job units and the feed mode. (Used in the step list format file) | Step Integer |

JOS(units)*10+JOS(fdmode) | PM, AM, FFM, PT, AT | ||

| units | The unit system the job information is stored in. | Job Integer |

Header | units | 0 = Inch 1 = Metric |

All |

| unspmode | A composite of the job units and speed mode. (Used in the step list format file) | Step Integer |

JOS(units)*10+JOS(spmode) | PM, AM, FFM, PT, AT | ||

| wc_desc | Description of the work cell or machine for the job. | Job String |

Work_cell | descrip | All | |

| width | The width of a grooving or punch tool. | Step Float |

Tool | width | PT, AT, AF | |

| wire_diam | The diameter of a wire electrode. | Step Float |

Tool | wire_diam | AW | |

| wire_speed | The wire speed for WEDM roughing and finishing. | Step Float |

Tool | wire_speed | AW | |

| wire_tension | The wire tension for WEDM roughing and finishing. | Step Float |

Tool | wire_tension | AW | |

| ws_section | The Section number of the work_setup data block in the current job. | Job String |

Work_setup | section | All | |

| ws_type | The Type (last four digits of Section number) number of the work_setup in the current .jof file. |

Job Integer |

JOS(ws_section) modulo 10000 | All | ||

| xset | The x offset for the tool. | Step Float |

Tool_assignment | xset | PT, AT | |

| yset | The y offset for the zx normal tool (obsolete). | Step Float |

Tool_assignment | yset | AT | |

| zset | The z offset for the tool. | Step Float |

Tool_assignment | zset | PT, AT | |

| zxnorm | Whether the tool is a zx normal tool (obsolete). | Step Integer |

Tool_assignment | zxnorm | AT |

Related Topics